(based on the PN-EN 1825 standard)

The nominal size should be calculated according to the following formula:

NS = Qmax· ft· fd· fr

where:

NS – nominal size of the separator

Qmax – maximum amount of sewage inflow into the separator in liters per second,

ft – factor including the temperature of the medium,

fd – factor including the density of a given fat / oil,

fr – factor including the utilization of detergents and rinsing agents.

After calculating, choose the closest larger nominal size 4 PN-EN 1825-1-2000

High waste water temperature reduces the efficiency of the grease separator. The temperature factors ft are listed in the table below.

Temperature factor ft

| Wastewater temperature inlet [ºC] | Temperature factor fx |

| ≤ 60 | 1,00 |

| Occasionally or frequently used > 60 | 1,30 |

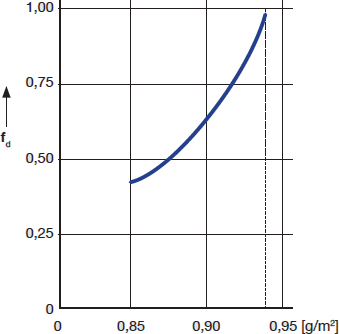

The density factor fd = 1.0 should be used for wastewater coming from the kitchen, slaughterhouse and meat or fish processing plants. In cases where oil characteristics are well known, the density factor can be determined from the following chart, where fd is specified for a range of grease or oils of various densities. For grease / oil density> 0.94 g / cm3 a density factor of 1.5 should be applied.

Factor fr including the use of detergents and rinsing agents:

| Use of detergent and rinsing agent | Factor fr including the use of detergents and rinsing agents |

| Never used | 1,00 |

| Occasionally or frequently used | 1,30 |

| Special cases, for example hospitals | ≥ 1,5 |

Settling tank capacity

(preceding the NIXOR-NT separator or composed with the NIXOR-NTO separator)

The capacity of the settlement tank, measured in liters, should be at least 100 NS, but for slaughterhouses or similar production the capacity should be at least 200 NS.

Aby zobaczyć pełną specyfikację produktu proszę otworzyć stronę na komputerze.